MÜLLERHEIM

Designed for Excellence – Our Commercial Grade Dinnerware.

Collections

-

702 Collection

The 702 Latte Cup Set is a perfect fusion of elegance and functionality,...

-

903 Collection

Introducing our 903 Collection, where form meets function in a symphony of...

-

510 Collection

Designed with practicality and aesthetics in mind by Passionate Espresso Lovers, us. Featuring...

Featured

702 Collection Latte Cup - Sapphire Shadow

903 Collection Side Plate Set Of 4 - Matte Snow White with Black Rim

903 Collection Side Plate Set Of 4 - Matte Greek Olive

MÜLLERHEIM

702 Collection Latte Cup - Vanilla Mist

Share

MÜLLERHEIM

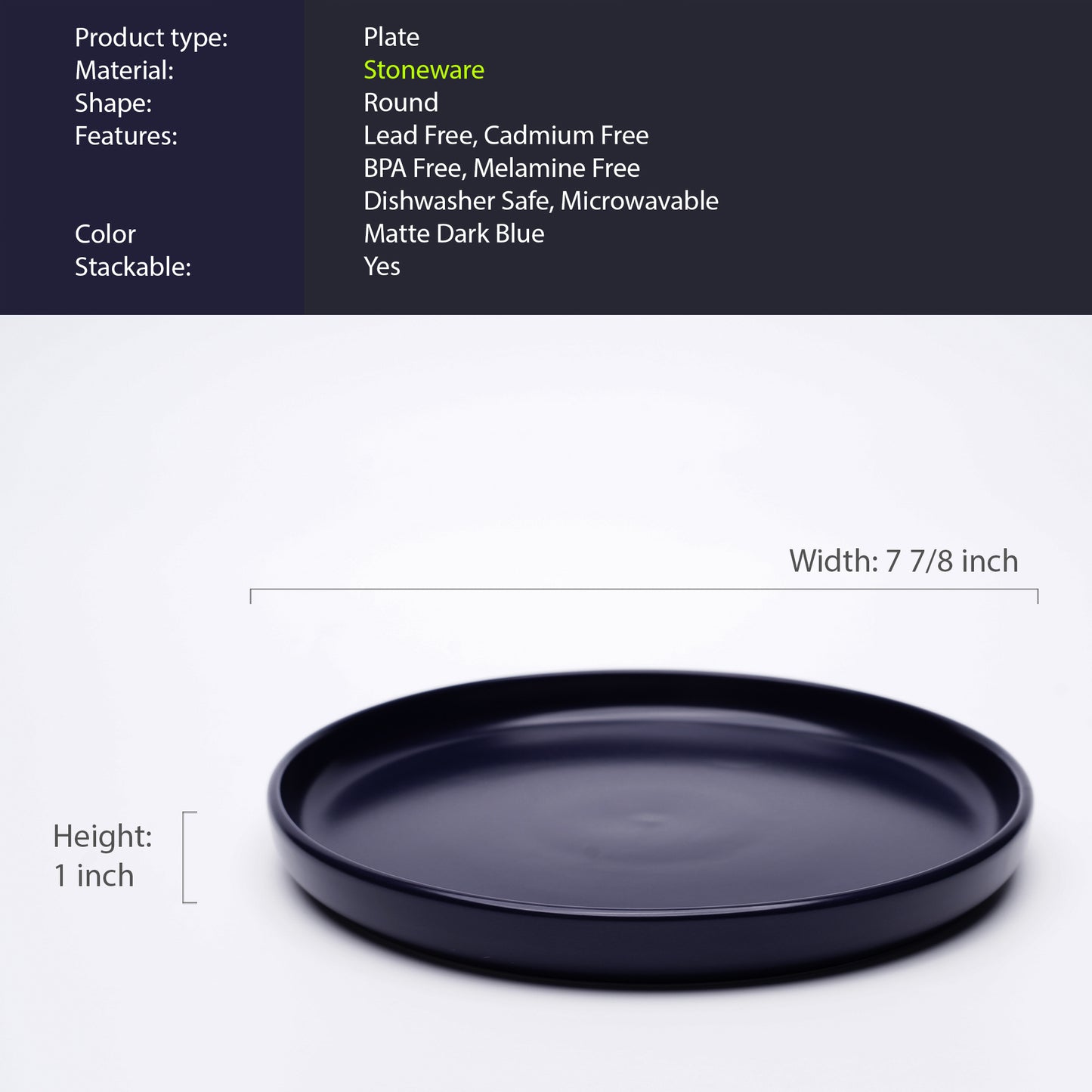

903 Collection Side Plate Set Of 4 - Matte Blueberry

-

Ceramic Manufacturing

There are different stations that will take you from the beginning of the process to the end. Preparation of raw materials, clay and glaze. Spray drying, pressing of ceramic and firing. Each step is equally important.

-

Glazing Process

They are dipped into color glaze and are baked for over 12 hours through the tunnel. Unlike painting, you don't see the the final color and finish before they come out from the kiln.

-

A Finished Piece of Ceramic

With the perfection of color glaze mixture, kiln temperature, firing time and, a perfect piece is created. Attention to detail is key.